Any questions? Contact our expert.

Vincent Bartolomei

Technical testing manager at Tera

vincent.bartolomei@groupe-tera.com

Home » Clean Rooms

Clean rooms are specialized environments designed to maintain extremely low levels of airborne particulates, pollutants, and contaminants. These controlled environments are critical in sectors such as pharmaceuticals, biotechnology, electronics, and medical device manufacturing, where even the smallest deviation in air quality can compromise product integrity and safety. To maintain these standards, the ISO 14644 series sets the international criteria for clean room classification and monitoring, focusing on the control of airborne particulates and cleanliness.

Ensuring compliance with these standards is not only a technical necessity but also a regulatory requirement in many industries. Tera-Sensor’s NextPM solution provides advanced particle monitoring capabilities that help facilities achieve and maintain these stringent standards, ensuring product quality and safety.

Understanding ISO 14644 and Regulatory Compliance

The ISO 14644 standard defines the classification and requirements for maintaining air cleanliness levels in clean rooms. It categorizes clean rooms based on the maximum allowable concentration of particles of specified sizes. For example, an ISO Class 5 clean room allows no more than 3,520 particles per cubic meter that are 0.5 microns or larger. Deviating from these requirements can lead to product contamination, increased risk of batch failure, and potential regulatory penalties.

In the European Union, clean rooms used for pharmaceutical production must also comply with EudraLex Volume 4, which outlines Good Manufacturing Practices (GMP) specific to the industry. Monitoring systems that provide continuous real-time data on particle concentration are crucial for maintaining compliance with these standards and ensuring that the environment remains within the acceptable parameters.

Impact of Poor Air Quality on Clean Room Operations

Even small fluctuations in particle concentration can significantly impact clean room operations. Contaminants such as dust, bacteria, or chemical vapors can lead to defects in semiconductor manufacturing or contamination in pharmaceutical products. This can result in costly recalls, damage to reputation, and potential legal repercussions.

Contamination control is the primary reason for strict air quality standards in clean rooms. Particulate contamination can lead to product loss, reduced yield, and compromised product safety. For example, in the pharmaceutical industry, airborne particulate contamination can affect the sterility of products, making them unsafe for human use. Real-time air quality monitoring with sensors like NextPM provides early warnings of potential contamination, allowing operators to take immediate corrective actions before the situation escalates.

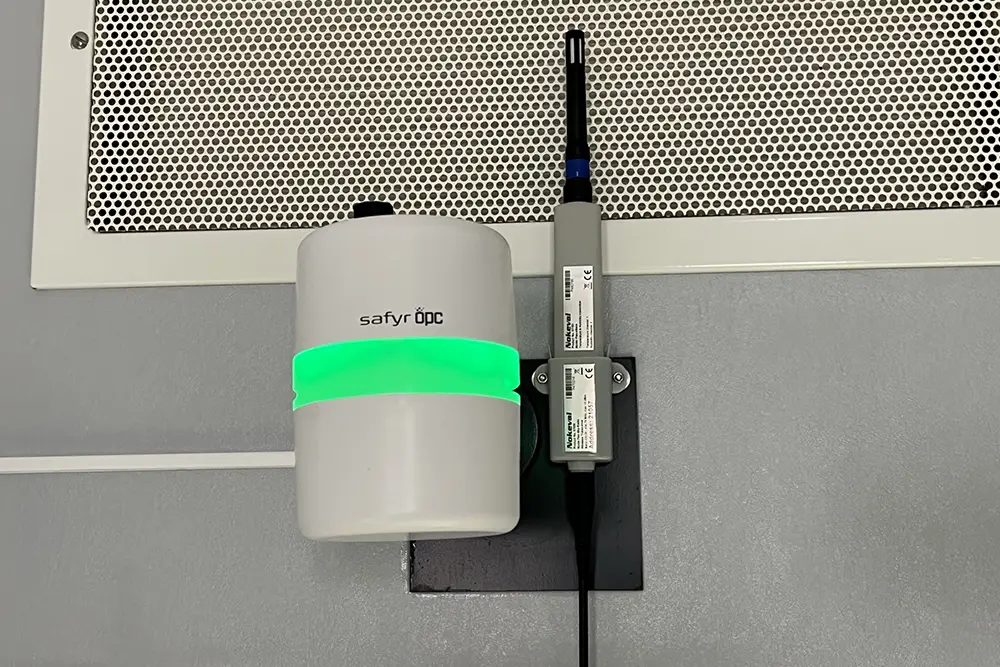

NextPM OPC

Designed for environmental monitoring and smart cities application, NextPM provides real time PM1, PM2.5 and PM10 measurements in µg/m3 and pcs/L.

PMSCAN

Designed for environmental monitoring and smart cities application, NextPM provides real time PM1, PM2.5 and PM10 measurements in µg/m3 and pcs/L.

Vincent Bartolomei

Technical testing manager at Tera

vincent.bartolomei@groupe-tera.com

The NextPM sensor offers several benefits that make it a leading solution for particulate matter (PM) monitoring across various applications.

The NextPM sensor is equipped with an automatic heater system that activates when the relative humidity exceeds 60%. This feature ensures measurement consistency by reducing the effect of humidity on particulate matter readings. Users can also manually control the heater through specific commands if needed. Additionally, the sensor’s sleep mode function helps conserve energy by stopping all non-essential operations when activated.

The NextPM sensor supports two main communication protocols:

The NextPM sensor is robust and versatile, making it ideal for industrial applications where continuous monitoring and high reliability are required. Its features include: