- Home

- Product Development

Product Development

TERA Sensor Engineering team also offers a full product development solution. Trust skilled and experienced professionals to develop the perfect product and solution for your needs.

Our approach can be explained in 5 main steps as follow :

- 1/ Product Conception Intelligence and Market Strategy: from Idea to Concept:

- Ideation: Collaborate with the client to generate ideas for the new product. Brainstorm features, usages, market needs and design concepts.

- Market Research: Analyze the target market, including customer needs, preferences, and competition. Identify market gaps and opportunities.

- Feasibility: Evaluate the technical, financial, and resource feasibility of the project. Determine if the project aligns with market needs.

- Project Scope: Define the project’s scope, objectives, and constraints. Create a project plan with timelines and milestones.

- 2/ Design and Development: from concept to prototype

- Concept Design: Create initial design concepts, including sketches, drawings, and prototypes. Review these concepts with the client for feedback and approval.

- Product Design: Develop comprehensive engineering drawings, 3D models, and specifications. Specify materials, components, and manufacturing processes.

- Electrical Design : we connect the sensors in local or within your Information System, Apps or Cloud

- Prototyping: Build physical prototypes or digital mock-ups to test and refine the design. Iterate based on testing and client feedback.

- Regulatory Compliance: Ensure the design complies with industry standards, safety regulations, and any applicable certifications.

- 3/ Testing and Validation:

- Functional Testing: Conduct rigorous testing to ensure the product functions as intended. Identify and address any performance or functionality issues.

- Quality Assurance: Implement quality control processes to maintain product quality throughout the development phase.

- User Testing: Involve potential users or clients in usability testing to gather feedback on user experience and make necessary improvements.

- Validation: Confirm that the product meets the initial requirements and objectives set by the client.

- Certification management within our sensor quality equipments and dedicated labs (CE, FCC, UL, TuV….)

- 4/ Production and Manufacturing: from prototype to production

- Manufacturability: Optimize the design for manufacturing, considering production methods, cost efficiency, and scalability.

- Supplier Selection: Identify and collaborate with suppliers for components and materials. Negotiate contracts and agreements.

- Production Setup: Plan production schedules, tooling, and assembly processes. Oversee manufacturing to ensure product consistency and quality.

- Quality Control: Implement quality control measures during manufacturing to identify and rectify defects.

- 5/ Launch and Post-Launch Support:

- Product Launch: Prepare for the product launch, including marketing strategies, distribution, and sales efforts.

- Documentation: Create user manuals, technical documentation, and support materials.

- Customer Support: Provide customer support to address inquiries, issues, and warranty claims.

- Continuous Improvement: Gather post-launch feedback and data to make product enhancements and plan for future iterations.

Throughout these stages, effective communication with the client is critical, a dedicated project manager as a central point of contact is always available with regular updates, milestone reviews, and client feedback integrated into the design and development process. This client-centric approach ensures that the final product aligns with the client’s vision and requirements.

Our Work

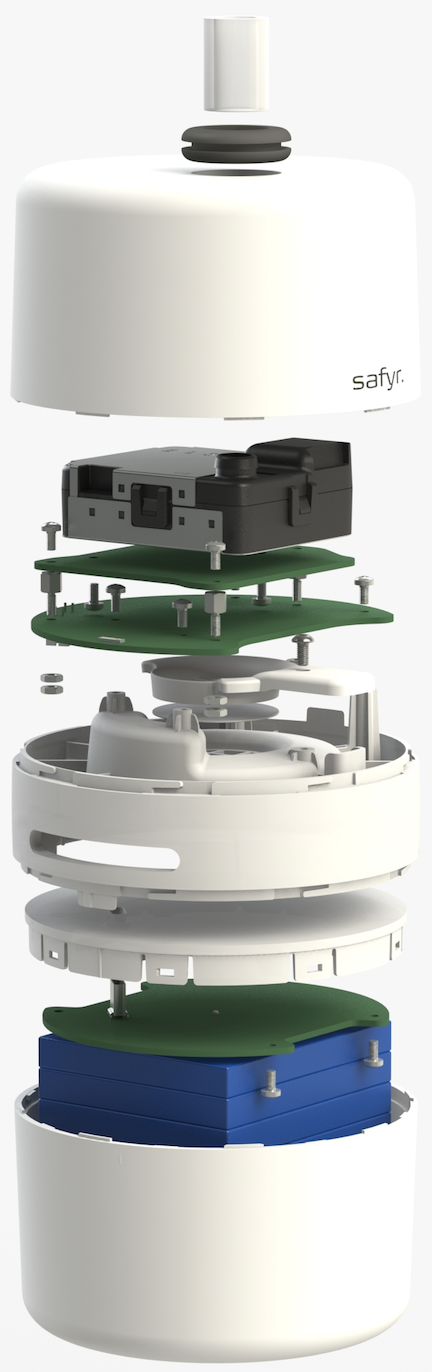

We wanted to develop a product able to reduce the risk of contamination on clean room production lines. We have collaborated for more than 2 years with experts from HEX, a company specializing in contamination control in critical environments. We have developed Safyr OPC, a high-precision sensor specially designed for monitoring fine particles in clean environments.

This new sensor, developed from our NextOPC, is integrated exclusively into the Safyr station.

Sleek design, perfectly smooth, without sharp edges, optimal for clean rooms. Safyr OPC is easily placed in your areas and equipment such as PSM, isolator, etc.

The OPC is also compatible with chemical and decontamination agents such as H2O2.