accuracy

ISO 14644-2 "Monitoring the maintenance of cleanroom performance for particulate air cleanliness"

real time

1 minute update frequency

autonomy

Up to 168 hours of battery life

LORA

869.5 MHz / 2.4 GHz Up to 400 m range

The rapid growth of the electric vehicle (EV) market brings with it a major challenge: the need to increase production of battery cells, essential components of EVs.

42

million electric vehicles in 2023

4000

FIRES CAUSED BY BATTERY THERMAL RUNAWAY

25%

EQUIPMENT FAILURE CAUSED BY PARTICLE BUILD-UP

The rapid growth of the electric vehicle (EV) market brings with it a major challenge: the need to increase production of battery cells, essential components of EVs. This growing demand is due to the increase in the number of EVs worldwide, from 7 million in 2019 to around 42 million in 2023. To meet this need, Europe and the United States are investing heavily in the construction of battery “gigafactories” on their territories, to compete with the currently dominant Chinese production.

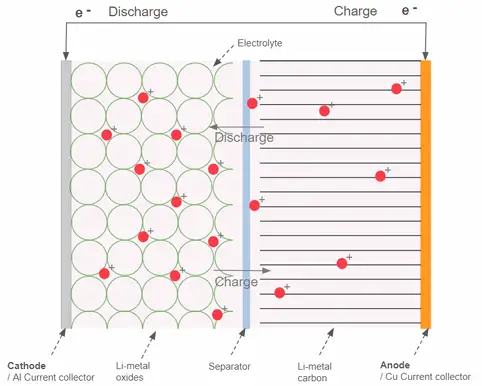

However, there are inherent risks in manufacturing Li-ion batteries. The materials used react with oxygen and humidity, generating explosive gases such as hydrogen, and dangerous gases such as hydrogen fluoride. What’s more, the use of toxic metals, notably cobalt in powder form, represents a danger to workers and the environment. One of the major problems to be solved is the formation of dendrites in battery cells, may cause thermal runaway and ignition or explosion of the battery. This phenomenon, caused by the growth of metallic structures between the electrodes,is amplified by the presence of contaminating particles during the assembly of battery components.

With ISO 14644, control requirements are the same as for cleanrooms

ISO 14644-2 "Monitoring the maintenance of cleanroom performance for particulate air cleanliness"

1 minute update frequency

Up to 168 hours of battery life

869.5 MHz / 2.4 GHz Up to 400 m range

Increase yields

Production safety

Worker safety

Trust

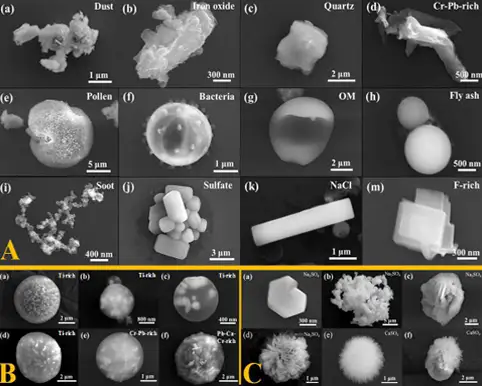

Although real-time monitoring is essential, it does not provide information on the chemical composition of particles. For a more in-depth analysis, sampling and laboratory analysis are recommended. This makes it possible to identify the exact nature of the particles and determine their potential impact on manufacturing processes and workers’ health.

Specialized laboratories, such as TERA Environnement in France, can carry out these analyses using standardized methods. In the event of a pollution peak detected by the real-time monitoring system, additional analyses are carried out to determine the chemical composition of the particles and to take appropriate measures, such as biological monitoring of potentially exposed workers..

Source : Journal of Environmental Protection

Vol.07 No.10(2016), Article ID:71021

Portrait and Classification of Individual Haze Particulates

Vincent Bartolomei

Technical testing manager at Tera

vincent.bartolomei@groupe-tera.com

The production of lithium-ion batteries, particularly for electric vehicles, poses major challenges in terms of safety and quality.

Cleanrooms are controlled environments where contamination by airborne particles is minimized. They play a crucial role in the production of lithium-ion batteries by :

Real-time monitoring of air quality is essential to guarantee an optimal production environment in gigafactories.