Services

Your Trusted Partner from Concept to Market

With you at every step of your product journey

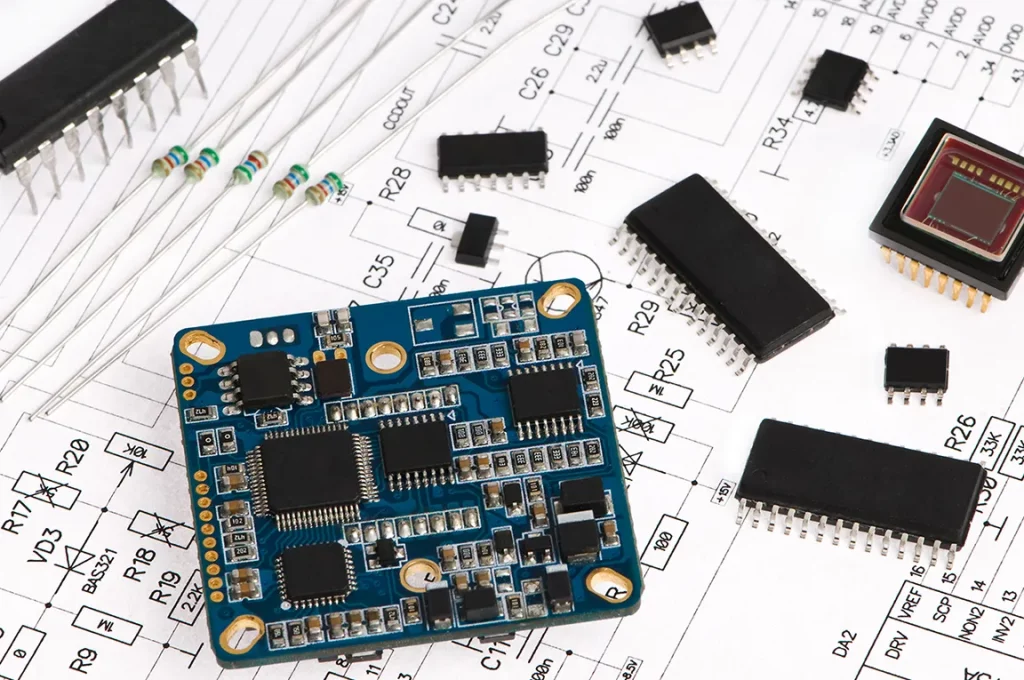

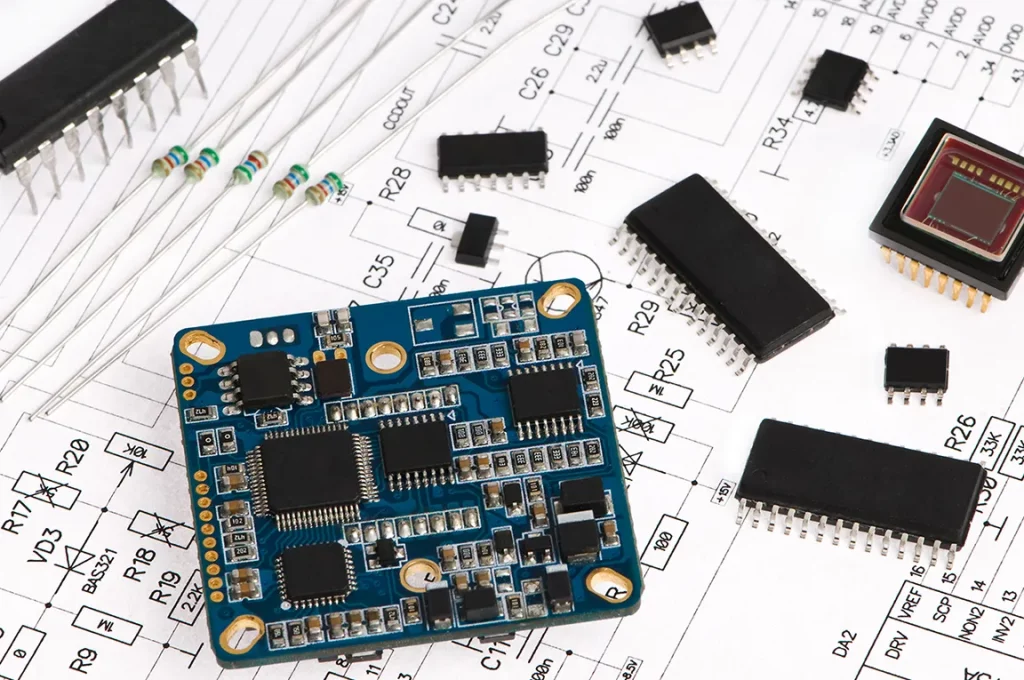

OEM Integration

We work closely with our clients to provide seamless OEM integration and professional services, ensuring a perfect fit for your unique requirements.

Prototyping

Product development

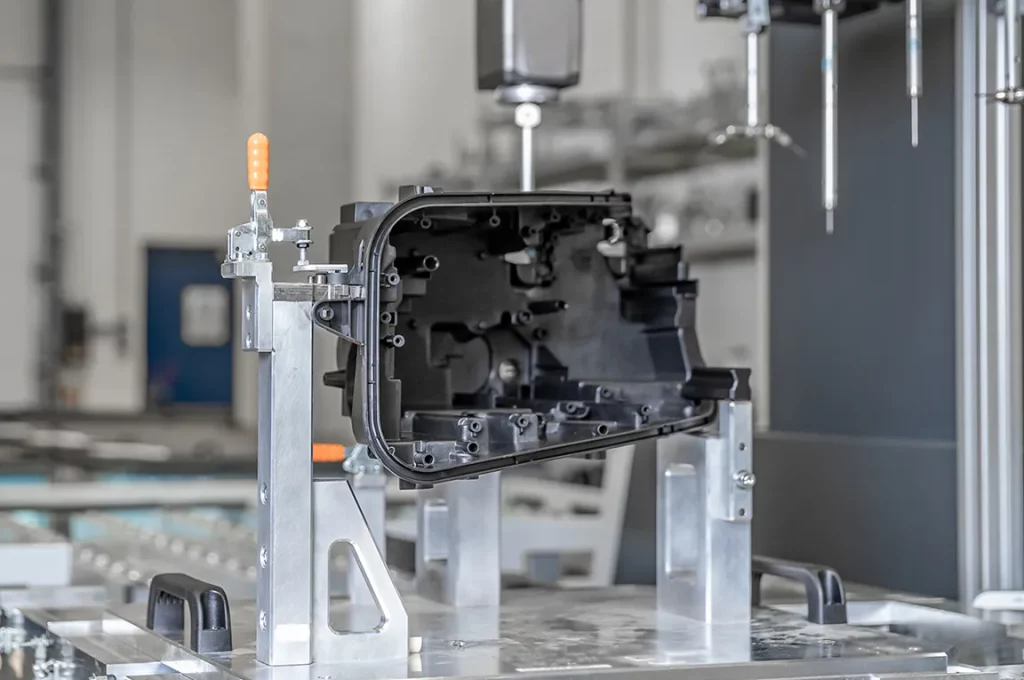

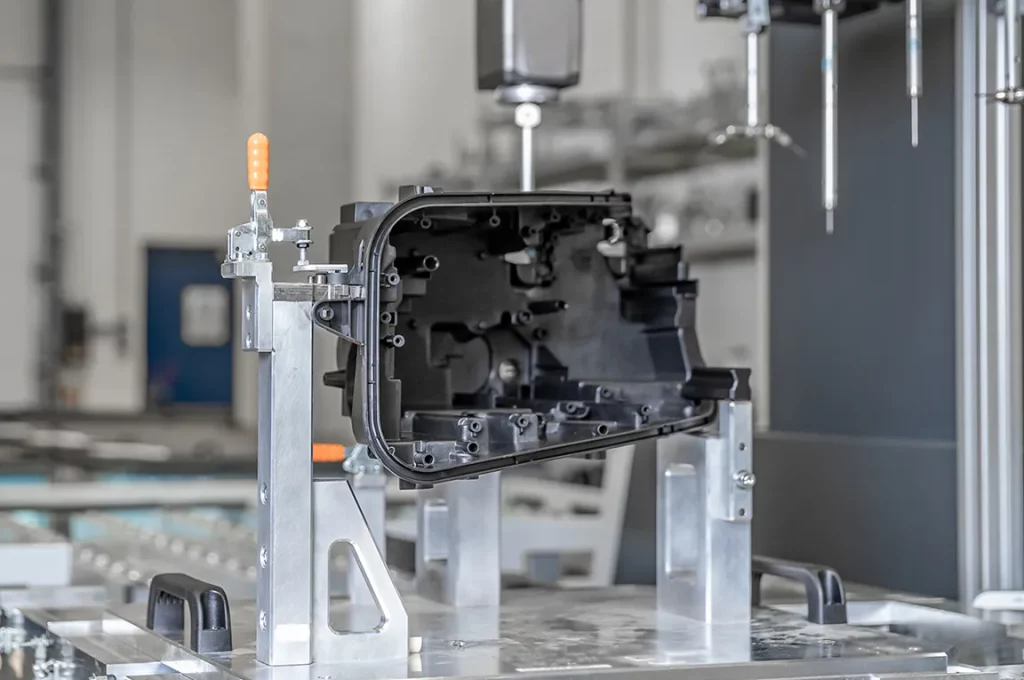

Test Systems

Our advanced test systems simulate real-world conditions, helping you validate the performance, accuracy, and durability of your air quality monitoring solutions.

Certification

We offer comprehensive testing and certification services to ensure your air quality sensors meet industry standards and regulatory compliance for market entry.

OEM Integration

TERA Sensor design office is now able to propose a full OEM integration service for its clients. Our hardware and software engineers will tailor a project to your need to create the perfect integration solution.

Planning and Requirements Gathering

– Define project scope, objectives, and requirements. Analyze technical specifications and regulatory constraints. Establish communication channels and identify key stakeholders.

Design and Development

Generate initial design concepts and alternatives. Develop detailed engineering drawings and documentation. Conduct prototyping and testing to refine the design. Specify materials, components, and manufacturing processes.

Production and Quality Control

Plan production schedules and coordinate with suppliers. Implement quality control processes and standards. Assemble components into the final product. Conduct integration testing and address compatibility issues.

Logistics and Delivery

Arrange for packaging and transportation logistics. Monitor inventory levels and manage supply chain. Ensure on-time delivery of integrated products to the OEM client.

Post-Integration Support and Closure

Provide post-integration technical support. Address warranty claims and post-integration issues. Complete project documentation and deliverables. Conduct a project review and gather lessons learned for future improvements.

Prototyping

TERA Sensor product development team has an extensive experience of developing state of the art prototypes for its clients.

The prototypes are within the critical path to success during the conception of a new solution.

Not only a prototype is necessary to validate all the technical aspect of the conception with extensives validation tests performed, it is a concretization of a future product to be commercialized.

Presenting an appealing prototype internally accelerates its adoption

Prepares for marketing and sales promotions

Test value proposition and engage first clients

Design review and validation

Iterative approach from 3D on a screen to real product.

Integration validation

All expertise are unified into a single product and all components such as mechanical parts, electronic boards, and sensors are assembled together to ensure proper fit.

Product validation

The technical functions of the product are validated, including sensors, connectivity, and embedded software, ensuring accurate measurements at the designated locations (gateway/bridge, cloud, smartphone apps, etc.).

Measurement qualification

Sensor qualification and validation with our air quality labs.

Final prototype

Acceptation of this coming product internally and within future customers. Our prototypes always look a like a final product in order to have everyone committed to success.

Product development

TERA Sensor Engineering team also offers a full product development solution. Trust skilled and experienced professionals to develop the perfect product and solution for your needs.

Throughout these stages, effective communication with the client is critical, a dedicated project manager as a central point of contact is always available with regular updates, milestone reviews, and client feedback integrated into the design and development process. This client-centric approach ensures that the final product aligns with the client’s vision and requirements.

Product Conception Intelligence and Market Strategy

– Ideation: Collaborate with the client to generate ideas for the new product. Brainstorm features, usages, market needs and design concepts.

– Market Research: Analyze the target market, including customer needs, preferences, and competition. Identify market gaps and opportunities.

– Feasibility: Evaluate the technical, financial, and resource feasibility of the project. Determine if the project aligns with market needs.

– Project Scope: Define the project’s scope, objectives, and constraints. Create a project plan with timelines and milestones.

Design and Development

– Concept Design

– Product Design

– Electrical Design

– Prototyping

– Regulatory Compliance

Testing and Validation

– Functional Testing: Conduct rigorous testing to ensure the product functions as intended. Identify and address any performance or functionality issues.

– Quality Assurance: Implement quality control processes to maintain product quality throughout the development phase.

– User Testing: Involve potential users or clients in usability testing to gather feedback on user experience and make necessary improvements.

– Validation: Confirm that the product meets the initial requirements and objectives set by the client.

– Certification management within our sensor quality equipment and dedicated labs (CE, FCC, UL, TuV….)

Production and Manufacturing

– Manufacturability: Optimize the design for manufacturing, considering production methods, cost efficiency, and scalability.

– Supplier Selection: Identify and collaborate with suppliers for components and materials. Negotiate contracts and agreements.

– Production Setup: Plan production schedules, tooling, and assembly processes. Oversee manufacturing to ensure product consistency and quality.

– Quality Control: Implement quality control measures during manufacturing to identify and rectify defects.

Launch and Post-Launch Support

– Product Launch: Prepare for the product launch, including marketing strategies, distribution, and sales efforts.

– Documentation: Create user manuals, technical documentation, and support materials.

– Customer Support: Provide customer support to address inquiries, issues, and warranty claims.

– Continuous Improvement: Gather post-launch feedback and data to make product enhancements and plan for future iterations.

Test systems

What sets our custom test systems apart is their adaptability. Each element can be abstracted to suit the unique requirements of various tests, accommodating different standards or the diverse nature of test items. This modular design ensures a remarkable level of interchangeability, a feature highly valued by our clients.

In essence, our custom test systems are a harmonious blend of advanced technology and user-centric design, crafted to excel in diverse applications while providing a high degree of customization to meet the specific needs of our clients.

Precise Sensor Technology

Our systems are equipped with state-of-the-art sensor technology. These sensors are finely tuned to provide real-time data on aerosol behavior, ensuring reliable and consistent results.

Programmable Logic Controllers

The intelligence behind our systems lies in the programmable logic controllers (PLCs). These controllers provide dynamic control and monitoring, enabling us to tailor each test to precise specifications.

User-Friendly Software

We understand that ease of use is crucial in complex testing environments. Our systems feature user-friendly software interfaces, empowering users to effortlessly configure, control, and retrieve data. This user-centric approach enhances efficiency and accessibility.

Tests & Certification

The creation of specific and robust testing methods and the monitoring of strict quality assurance have always been the pillars of Groupe TERA. For more than 10 years, TERA Sensor has been developing products, tools and sensors for its customers’ different markets. This experience made it possible to develop know-how in understanding and applying the standards to be respected for marketing a solution. We propose to share this know-how and our laboratory with you in order to free you from this constraint and focus on your core business.