Technology

NextPM

The Cutting-Edge Solution for Particulate Matter Monitoring

A new era in dust monitoring

At Tera-Sensor, we are committed to advancing air quality measurement through innovation and precision. Our NextPM sensor, designed with over 20 years of expertise in particulate matter monitoring, offers unrivaled performance in measuring PM1, PM2.5, and PM10.

This sensor, developed under three patents, is built for real-time monitoring, delivering unparalleled accuracy, durability, and long-term reliability. NextPM’s unique features make it the optimal solution for both environmental monitoring and industrial applications.

A new era in dust monitoring

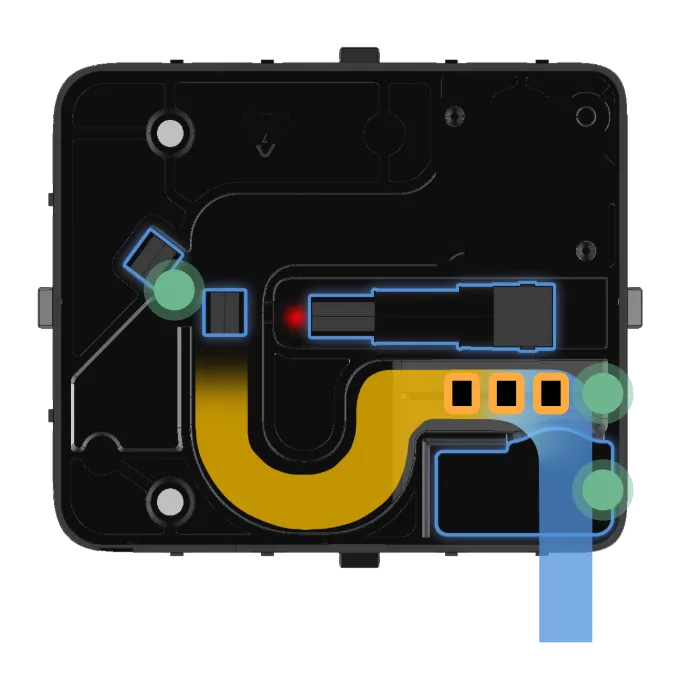

2 detection angles

This feature is unique in this category of optical sensors. Gives a better resolution by the discrimination of particles that could have the same signals at 90°.

Coarse particle trap

Unique feature avoiding the use of an additional physical filter, improving the sensor lifetime by avoiding premature clogging of the flow. Filter blocking particles > 10 µm.

Humidity shield

NextPM can heat the flow to regulate humidity. No impact of temperature on the measure. Unique and worldwide patent to keep the humidity inside the sensor low enough to avoid “growth factor” effect. Increase lifetime without maintenance.

Key benefits

High Accuracy

Due to its proprietary optical architecture and TERA Sensor unique algorithm, the NextPM is the best sensor to size particles. For this kind of technology, an effective sizing is the former key to a precise PM measurement.

Quality product

Each part of NextPM has been specifically designed, crafted and tested by our team based in France in order to meet the highest quality standards and provide the most reliable technology.

Cost Efficiency

With up to 10 years without maintenance, NextPM offers optimal total costs of ownership by reducing maintenance operations.

Reliability

NextPM integrates dedicated reliable components to remove temperature and humidity interferences on measurement so you can use the technology in a wide use case’s range.

Field-Tested and Globally Validated

NextPM has been rigorously tested and verified by several independent institutions, including the South Coast AQMD’s AQ-SPEC program in California and France’s LCE/AtmoSud. These studies demonstrate the sensor’s reliability and accuracy in various environmental conditions, reinforcing its status as one of the most precise low-cost PM sensors available.

Click here for access to full reports.

NextPM compared to the competition

To help chose the best PM sensor based on your specific requirements we created this interactive chart that gives you the possibility to do a side by side comparison.

Data comes from independent studies you can find below.

A wide range of applications

FAQ

Q: What are the main advantages of using the NextPM sensor for particulate matter monitoring?

The NextPM sensor offers several benefits that make it a leading solution for particulate matter (PM) monitoring across various applications.

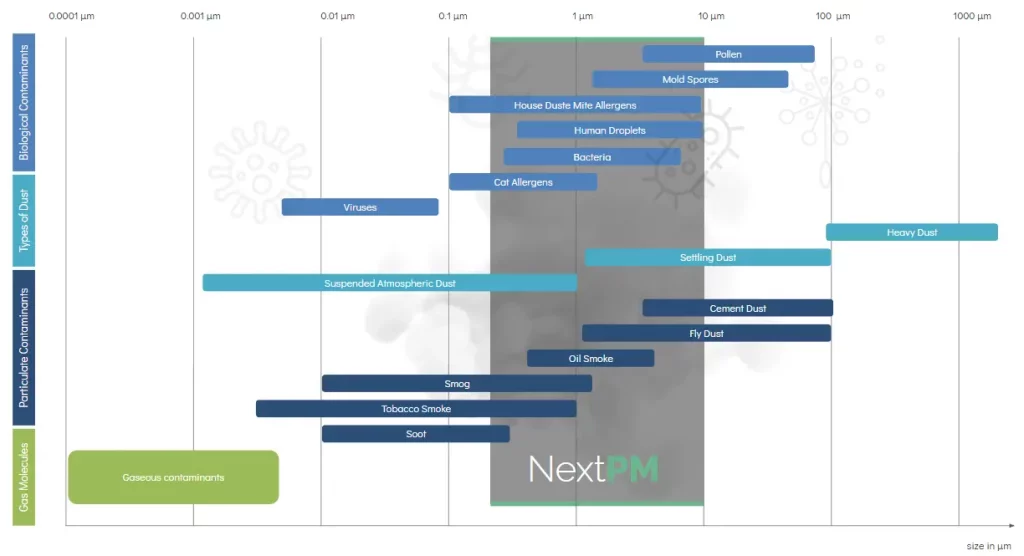

High Accuracy: The NextPM sensor ensures reliable PM measurements with high precision, detecting particles as small as 0.3 µm and providing readings for PM1, PM2.5, and PM10.

Wide Detection Range: It covers a broad range of particle sizes, from 0.3 µm to 10 µm, allowing for comprehensive monitoring of different pollutants in the environment.

Durability: With a lifespan exceeding 10,000 operational hours, the NextPM sensor is designed for long-term use in demanding environments.

Low Power Consumption: The sensor consumes less than 70mA in active mode and even less in sleep mode, making it energy-efficient.

Adaptability: It features an internal heater that automatically activates to maintain measurement accuracy under high humidity conditions.

Q: How does the NextPM sensor manage different environmental conditions?

The NextPM sensor is equipped with an automatic heater system that activates when the relative humidity exceeds 60%. This feature ensures measurement consistency by reducing the effect of humidity on particulate matter readings. Users can also manually control the heater through specific commands if needed. Additionally, the sensor’s sleep mode function helps conserve energy by stopping all non-essential operations when activated.

Q: What communication protocols does the NextPM support?

The NextPM sensor supports two main communication protocols:

- Proprietary UART Frames: The default communication method, providing simple commands for reading and writing data.

- Modbus Serial Protocol (TTL 3.3V): An industrial standard communication protocol that allows more flexibility and integration capabilities, especially in automated systems. This dual protocol capability enables the NextPM to be used in a variety of setups, from standalone operations to complex network integrations.

Q: What makes the NextPM sensor suitable for industrial applications?

The NextPM sensor is robust and versatile, making it ideal for industrial applications where continuous monitoring and high reliability are required. Its features include:

- Resilience in Harsh Conditions: Capable of operating in temperatures ranging from -20°C to +70°C and in non-condensing environments of up to 95% humidity.

- Compliance: The sensor is CE, REACH, and RoHS compliant, ensuring that it meets international standards for safety and environmental impact.

- Ease of Integration: With options for open or sealed casings, it can be seamlessly integrated into HVAC systems or standalone air quality monitors.