Smart Industry Monitoring

NextPM for Industrial Air Quality Monitoring

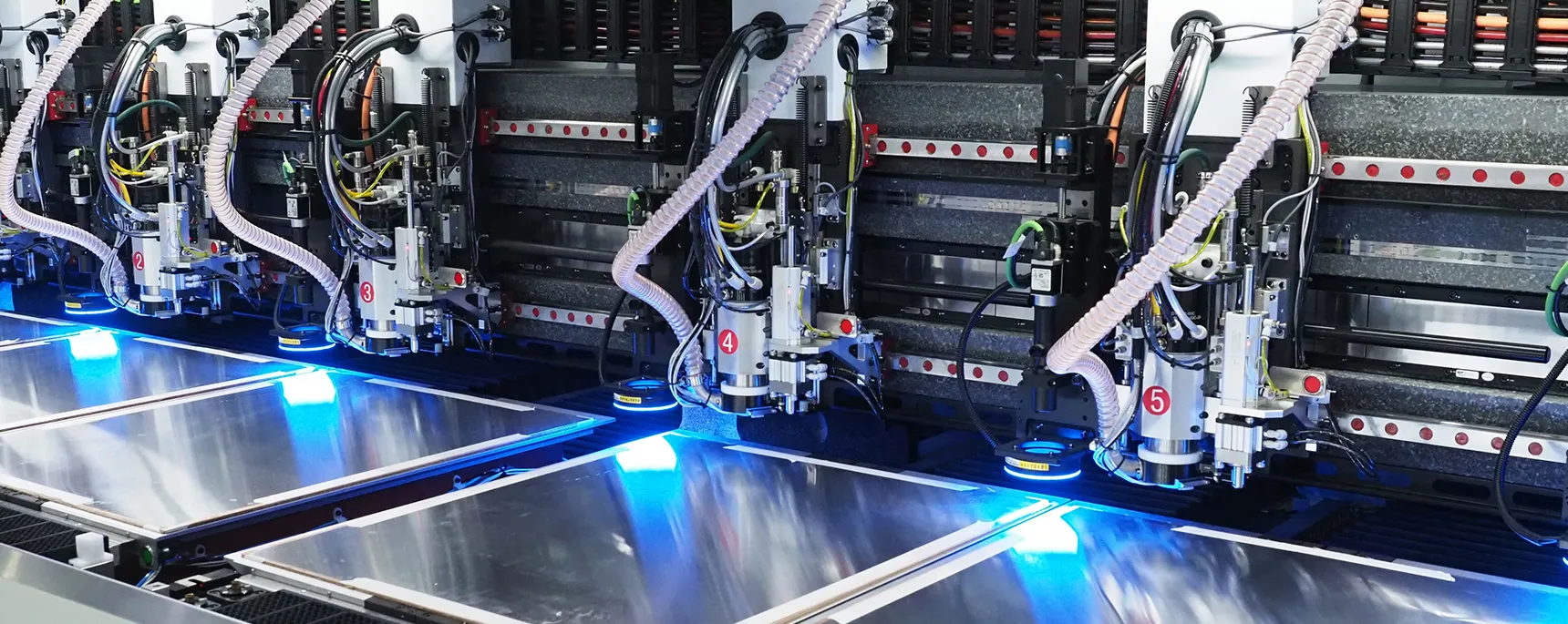

In modern industry, controlling airborne particles is no longer optional. From protecting sensitive manufacturing processes to ensuring worker health and complying with strict regulations, real-time particulate monitoring has become a cornerstone of smart industry operations.

NextPM enables factories, clean workshops, and HVAC-controlled environments to monitor PM1, PM2.5, and PM10 continuously, even under challenging humidity and temperature conditions. This ensures consistent production quality, reduced downtime, and safer workplaces.

Challenges: Accuracy and Harsh Conditions

Industrial environments often combine dust, fumes, variable humidity, and strong airflow variations, which can lead traditional low-cost PM sensors to fail.

- Accuracy issues: fluctuating humidity causes particles to swell, resulting in misleading measurements.

- Durability problems: moisture and contaminants can damage sensors and increase maintenance.

- Operational risks: unreliable data makes it harder to anticipate filter clogging, identify emission leaks, or maintain compliance with health and safety standards.

Innovative Solutions for Reliable Industrial PM Monitoring

Patented Humidity Control

NextPM integrates an active heating system that removes excess moisture from the airflow, eliminating the “growth factor” effect and ensuring stable, drift-free measurements.

Patented Humidity Control

With its robust design and coarse particle trap, NextPM resists clogging and damage from larger particles, extending sensor lifetime to up to 10 years without maintenance.

Granular Insights

Beyond standard PM1/PM2.5/PM10, NextPM provides 5 particle size channels (0.3 to 5 µm), giving operators valuable insights for predictive maintenance, emission control, and process optimization.

Why use NextPM in Smart Industry?

Compliance & Quality Assurance

Meet regulatory standards (ISO, GMP, occupational health) with trustworthy data validated against reference instruments.

Cost-Efficiency

Reduce downtime and unexpected maintenance by relying on a sensor designed for industrial-scale use and long lifetime.

Predictive Maintenance

Anticipate filter replacement, detect abnormal emissions early, and optimize HVAC systems to lower energy costs.

Seamless Integration

Supports UART/Modbus protocols for direct integration into BMS, SCADA, or IoT platforms.

FAQ

Q: How does NextPM ensure reliable measurements in humid factories?

Its patented humidity management removes water vapor from sampled air, preventing particle swelling and measurement bias.

Q: What is the lifetime of NextPM in industrial conditions?

With minimal maintenance, NextPM can operate for up to 10 years, thanks to its clog-resistant design and robust components.

Q: What communication protocols are available for industrial integration?

NextPM supports UART and Modbus, making it directly compatible with most industrial automation systems.