- Home

- Prototyping

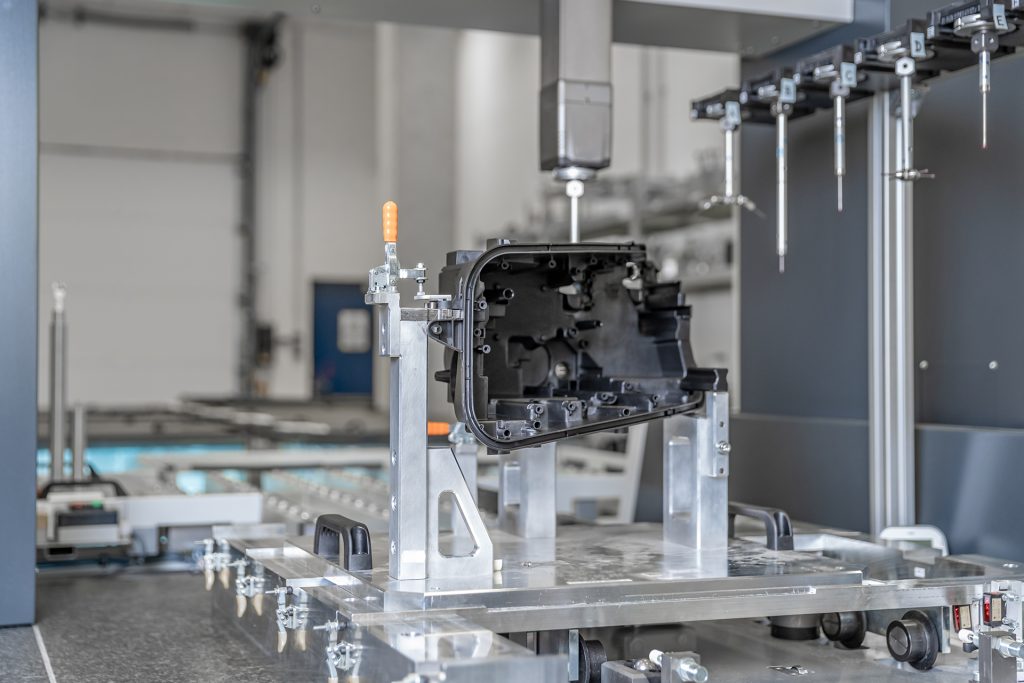

Prototyping

TERA Sensor product development team has an extensive experience of developing state of the art prototypes for its clients.

The prototypes are within the critical path to success during the conception of a new solution.

Not only a prototype is necessary to validate all the technical aspect of the conception with extensives validation tests performed, it is a concretization of a future product to be commercialized.

The qualification and validation phases within prototype are :

1. Design review and validation : Iterative approach from 3D on a screen to real product

2. Integration validation : all expertise are unified into a single product and all components such as mechanical parts, electronic boards, and sensors are assembled together to ensure proper fit.

3. Product validation : The technical functions of the product are validated, including sensors, connectivity, and embedded software, ensuring accurate measurements at the designated locations (gateway/bridge, cloud, smartphone apps, etc.).

4. Measurement qualification : sensor qualification and validation with our air quality labs

5. Acceptation of this coming product internally and within future customers. Our prototypes always look a like a final product in order to have everyone committed to success:

– Presenting an appealing prototype internally accelerates its adoption.

– Creating a prototype with a finished appearance prepares for marketing and sales promotions of the upcoming product, targeting key accounts, preliminary prospects, and beyond.